ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Rexxam’s Unique Equipment to Yield Better Performance

It has been 50 years since Rexxam Co., Ltd. started designing and manufacturing electronic controllers. Specifically, Rexxam’s core business encompasses integrated design from circuit design to board manufacturing and casing. Thus, covering a wide range of users such as air conditioning-related, consumer, factory automation, automotive, and medical equipment.

In Japan, the company has 10 plants in the Shikoku region with a total site area of 480,000sq.m. In addition, the company has also been maintaining overseas bases. Namely, in Suzhou and Shenzhen in China; Samutprakarn in Thailand; Uttar Pradesh in India; and Prestice in the Czech Republic. Overall, the monthly production capacity of all bases ranges from 1.2 to 1.5 million standard substrates.

Because of the expansion of production volumes, Rexxam has been considering more efficient and labor-saving operations.

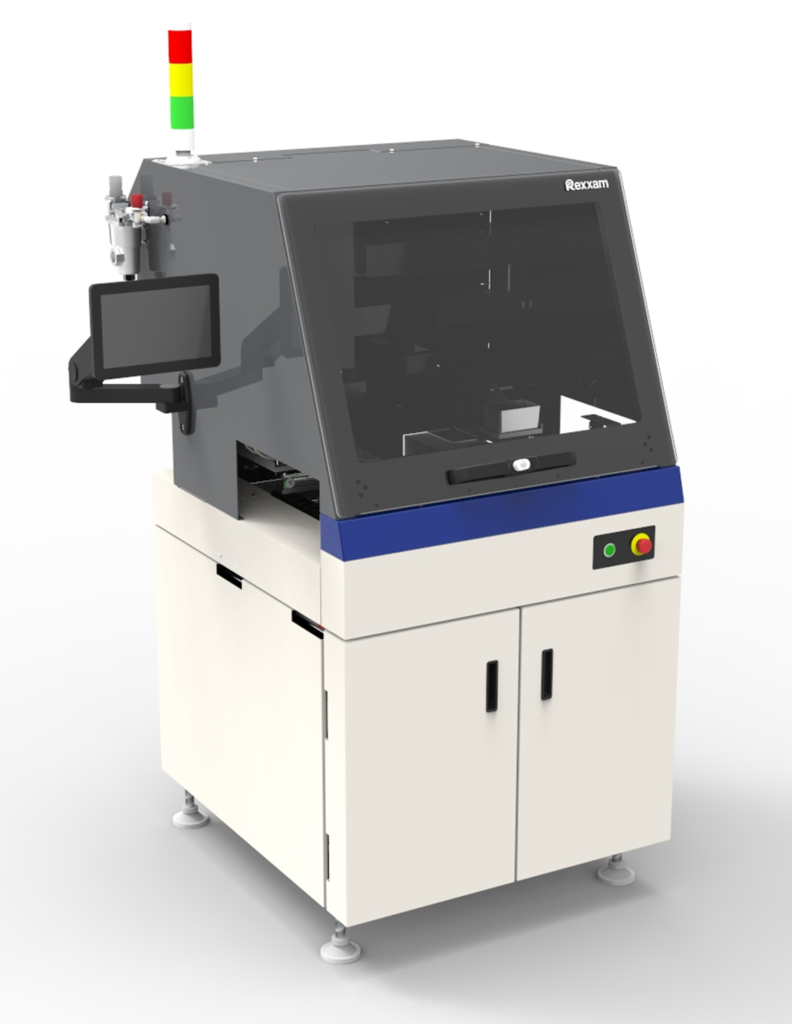

Rexxam had initially adopted an inspector from another manufacturer. However, the company sees the need for a more efficient and easy-to-use inspection machine. For that reason, the company began developing a PCB visual inspector. It will integrate the image processing and optical design technologies it has cultivated through the years.

Employs Deep Learning

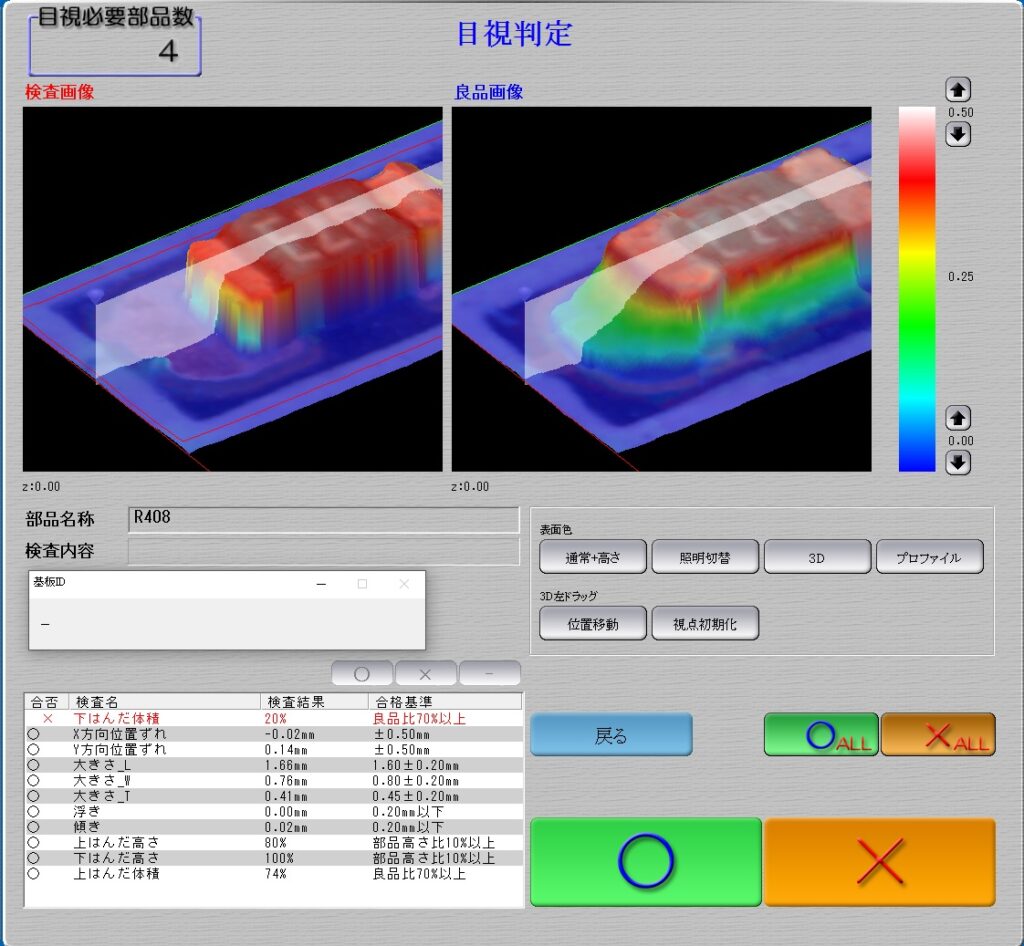

In PCB mounting, a system must detect defects that occur during the manufacturing process. In addition, it also needs to inspect a wide variety of mounted components as high speed with high accuracy without omissions. Thus, PCB visual inspector must easily generate inspection data. This will shorten the start-up time for inspecting boards produced in small lots in high-mix, low-volume production.

Although Rexxam is constantly improving and upgrading its hardware and software, the creation of inspection data relies on manpower. Therefore, this process may yield inspection errors and false alarms. Furthermore, experience and skill are necessary to become proficient in data creation.

Rexxam has achieved a breakthrough in software development by introducing Deep Learning, an AI technology. Deep Learning enables automatic recognition of the type and position of components. Specifically, such as square chips and ICs from the board image, which was difficult with conventional technologies.

The push of a button dictates the operation of the automatic component setting. Hence, eliminating the need for specialized setting work. While conventional functions vary in data creation time and quality depending on the skill level of the operator, the automatic parts setting function allows anyone to create accurate and identical data in a short time.

In addition, when used in combination with mounter data, a full parts library that can be deployed to create inspection data for other boards can be created, thus completing data with uniform inspection accuracy for a wide variety of boards.

The application of Deep Learning has also been effective in character inspection. Particularly, by reducing false positives due to special fonts and blurred characters. The 3D inspector, which inspects using height information in addition to 2D images, can detect solder balls on the entire surface of the board. Thus, eliminating the need for adjustment to the location and shape of the solder balls.

Moisture-Proof Coating, Drying Equipment

Rexxam has been developing mainly inspection equipment, but the production process is wide-ranging. Specifically, from SMT to flow and coating processes, and the requirements are also diverse.

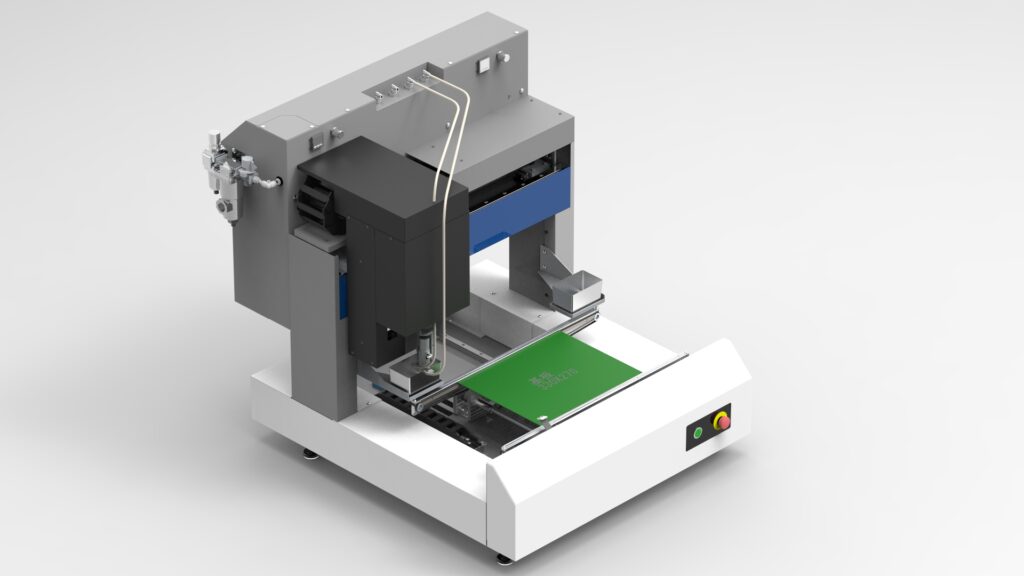

For substrate coating equipment used in the dispensing process, Rexxam launched in 2021 a lineup of in-line and tabletop types. Two types of in-line type coating nozzles, film coating type, and needle type come as standard. Moreover, the inline type can apply moisture-proofing agent to a large area in a short time and precisely to a limited area.1

It is possible to identify the application area while monitoring the entire substrate image. In addition to setting the application direction and nozzles for each application area, the system also checks the front and back of the substrate and the direction of transport.

In addition, the simulation function enables prior confirmation of the application route by searching for the shortest application route. Therefore, contributing to shorter takt time. A φ150 exhaust duct is available at the rear of the machine to collect odors.

Volatile solvents contained in moisture-proof materials are harmful to the human body, but have been allowed to dry naturally indoors. To suppress the emission of solvents, ventilation of the entire work area alone is ineffective. Moreover, there is a strong need to improve the work environment by reducing the waiting time until drying. Also, venting the solvents from the equipment from the time of their generation and automation of the application and drying processes.

Therefore, Rexxam has developed a moisture-proof agent dryer, which it will introduce to the market this year. Particularly, it can achieve a drying time of approximately 30 seconds by applying infrared heating and hot air to substrates.

Since the transfer speed is variable, it is possible to set the drying time according to the production tact time. Moreover, the effective substrate width ranges from 50 to 250mm, and the conveyor clearance is 80mm vertically to accommodate taller components. Efficient discharge of organic solvents through exhaust ducts supports reduction of health hazards.

In conjunction with the substrate coating equipment, the system not only reduces the time required for the coating to drying process. What is more, it can provide stronger support for improving the work environment.

Note:

1 Only the film-coated type is available for the tabletop type.

-24 April 2024-